The Importance of Regular Safety Audits for Electrical Systems

Table Of Contents

The Process of Conducting a Safety Audit

Conducting a safety audit involves a systematic approach that ensures comprehensive evaluation of electrical systems. The process typically begins with a preliminary assessment, which gathers initial data about the current state of the electrical infrastructure. This may include reviewing existing documentation such as wiring diagrams, maintenance records, and previous audit reports. Engaging stakeholders early on can offer valuable insights and help identify specific areas of concern that require closer scrutiny.

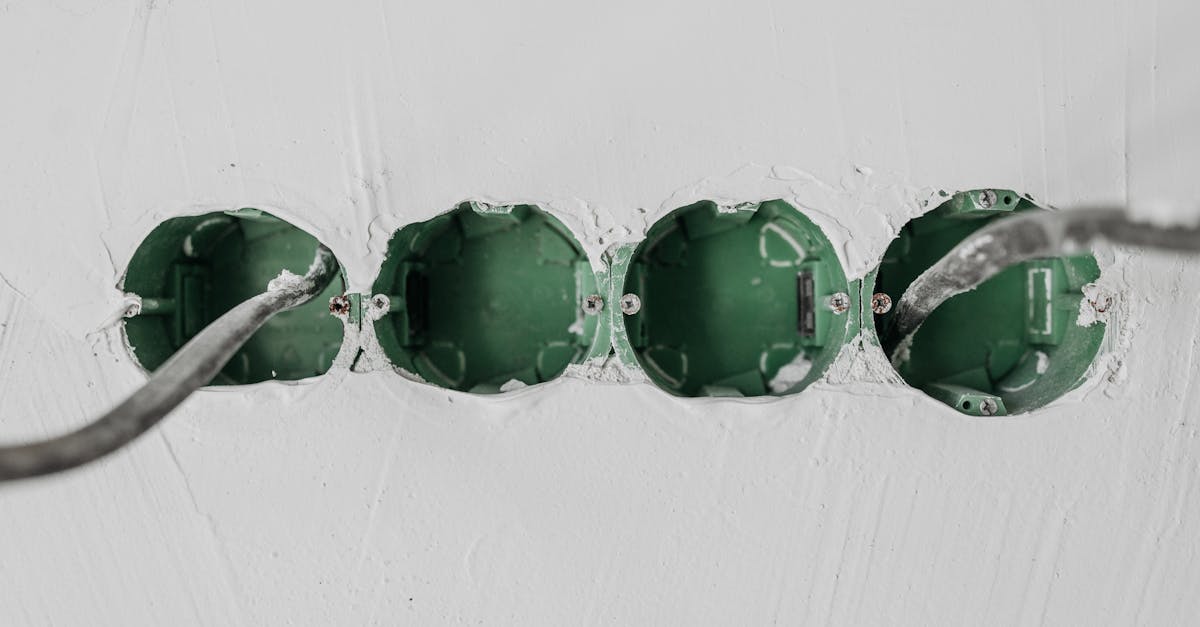

Once the preliminary data is collected, the audit team proceeds with a detailed inspection of the electrical systems in question. This step necessitates a thorough on-site examination, where various components like circuit breakers, transformers, and wiring are evaluated against established safety standards. The use of checklists helps to maintain consistency throughout the audit, ensuring that all critical aspects are covered. Following the inspection, the findings are compiled into a comprehensive report that outlines any identified deficiencies and recommendations for corrective action.

Step-by-Step Guide to Effective Auditing

Conducting an effective safety audit begins with a comprehensive planning phase. This involves defining the scope and objectives of the audit, ensuring that all relevant electrical systems and components are included. Engaging with stakeholders is crucial during this stage, as their insights can highlight specific concerns and areas that require closer examination. A schedule should be established, outlining the timeline for the audit process while also accounting for necessary resources and personnel.

Once the planning is complete, the next step involves a thorough site inspection. Auditors should meticulously examine electrical equipment, wiring systems, and safety documentation for compliance with applicable standards. Observations made during this phase should be recorded in detail, as these will inform the subsequent analysis. After collecting all relevant data, auditors can evaluate findings against established safety criteria, identifying potential hazards and areas for improvement, which will form the basis for recommendations and enhancements to the electrical systems in question.

Tools and Technologies for Safety Audits

In the rapidly evolving field of electrical safety, a variety of tools and technologies have emerged to streamline the auditing process. Digital inspection software allows auditors to conduct thorough examinations more efficiently by providing pre-set checklists and automated reporting features. Mobile devices equipped with specialised applications can enhance the ability to document findings on-site, reducing the chances of oversight. Such technologies not only improve accuracy but also facilitate collaboration among team members through cloud-based platforms, ensuring that insights and data are easily accessible.

Utilising advanced testing instruments is equally crucial for identifying potential hazards within electrical systems. Thermal imaging cameras can detect heat anomalies that may indicate faulty wiring or overloading equipment. Additionally, earth leakage circuit breakers and insulation resistance testers offer insights into the integrity of electrical installations. These innovative solutions empower safety professionals to conduct comprehensive assessments, promoting a proactive approach to maintaining compliant and secure electrical systems.

Innovative Solutions for Accurate Assessments

Advancements in technology have transformed the way safety audits are conducted in electrical systems. Drones equipped with thermal imaging cameras enable auditors to inspect hard-to-reach areas. This innovation allows for the identification of overheating components or faulty connections without requiring extensive scaffolding or dangerous climb operations. Furthermore, the integration of software tools for data collection enhances the accuracy and efficiency of the auditing process. With real-time data analysis, auditors can quickly identify anomalies and generate comprehensive reports.

Automation is also making significant strides in the realm of safety assessments. Smart sensors installed in electrical systems continuously monitor performance metrics, alerting personnel to irregularities before they escalate into serious issues. This proactive approach complements traditional auditing methods and ensures a more thorough oversight. Utilising artificial intelligence, predictive analytics can forecast potential failures based on historical data and usage patterns, providing invaluable insights that drive preventive maintenance strategies.

Case Studies

Examining real-world instances of successful safety audits provides valuable insights into best practices. One notable case involved a large manufacturing facility that conducted a comprehensive audit of its electrical systems. The audit revealed several critical areas of concern, including outdated wiring and insufficient safety protocols. Prompt action was taken to address these issues, resulting in a significant reduction in incidents related to electrical safety and a marked improvement in overall operational efficiency.

Another example comes from a healthcare institution that underwent a rigorous safety audit following a series of minor electrical mishaps. The findings led to an overhaul of their maintenance schedule and the implementation of a new training module for staff regarding electrical safety practices. Not only did this proactive approach prevent further incidents, but it also fostered a safety-conscious culture among employees, highlighting the long-term benefits of regular audits in enhancing safety standards and reducing risks.

Lessons Learned from Real-World Implementation

Real-world implementation of safety audits has highlighted the necessity of fostering a culture of safety within organisations. Engaging employees at all levels in the auditing process not only improves compliance but also enhances overall awareness of electrical safety issues. Training sessions and workshops have proven effective in encouraging staff participation and instilling a sense of shared responsibility. By making safety a collaborative effort, teams are more likely to identify potential hazards and rectify them proactively.

The integration of modern technology during audits has resulted in more accurate assessments of electrical systems. Tools such as digital checklists and analysis software streamline data collection and enhance the evaluation process. Additionally, employing thermal imaging cameras allows for the early detection of overheating components, which may lead to failures if left unaddressed. Adopting these innovative measures not only increases the effectiveness of audits but also provides valuable insights that can inform future safety strategies.

FAQS

What is a safety audit for electrical systems?

A safety audit for electrical systems is a comprehensive evaluation designed to identify potential hazards, ensure compliance with safety standards, and assess the overall reliability and safety of electrical installations.

How often should electrical systems undergo safety audits?

Electrical systems should ideally undergo safety audits at least once a year. However, this frequency may vary based on the complexity of the systems, regulatory requirements, and any significant changes or incidents that occur.

What are the key benefits of conducting regular safety audits?

Regular safety audits help identify and mitigate risks, ensure compliance with legal and industry standards, prevent accidents and downtime, and ultimately protect both personnel and equipment from electrical hazards.

What tools and technologies are essential for conducting effective safety audits?

Essential tools for safety audits can include thermal imaging cameras, multimeters, insulation resistance testers, and software for data analysis and reporting. These tools help in accurately assessing electrical systems and identifying potential problems.

Can you provide an example of a successful safety audit case study?

One example of a successful safety audit case study is a manufacturing plant that identified several electrical hazards, leading to the implementation of corrective measures. As a result, they reduced incidents of electrical failures by 40%, improved workplace safety, and ensured compliance with updated safety regulations.

Related Links

Trends in Electrical Safety Training for Commercial ElectriciansUnderstanding the Latest Enhancements in Electrical Safety Protocols

How IoT is Revolutionising Electrical Safety Standards in the Industry

Best Practices for Implementing Advanced Electrical Safety Measures

Examining New Electrical Safety Legislation and Its Implications

Evaluating the Effectiveness of Modern Electrical Safety Equipment

The Influence of Smart Monitoring Systems on Electrical Safety

Key Innovations Shaping the Future of Electrical Safety for Businesses

The Role of Technology in Improving Electrical Safety Compliance