Best Practices for Maintaining Electrical Safety in Workplaces

Table Of Contents

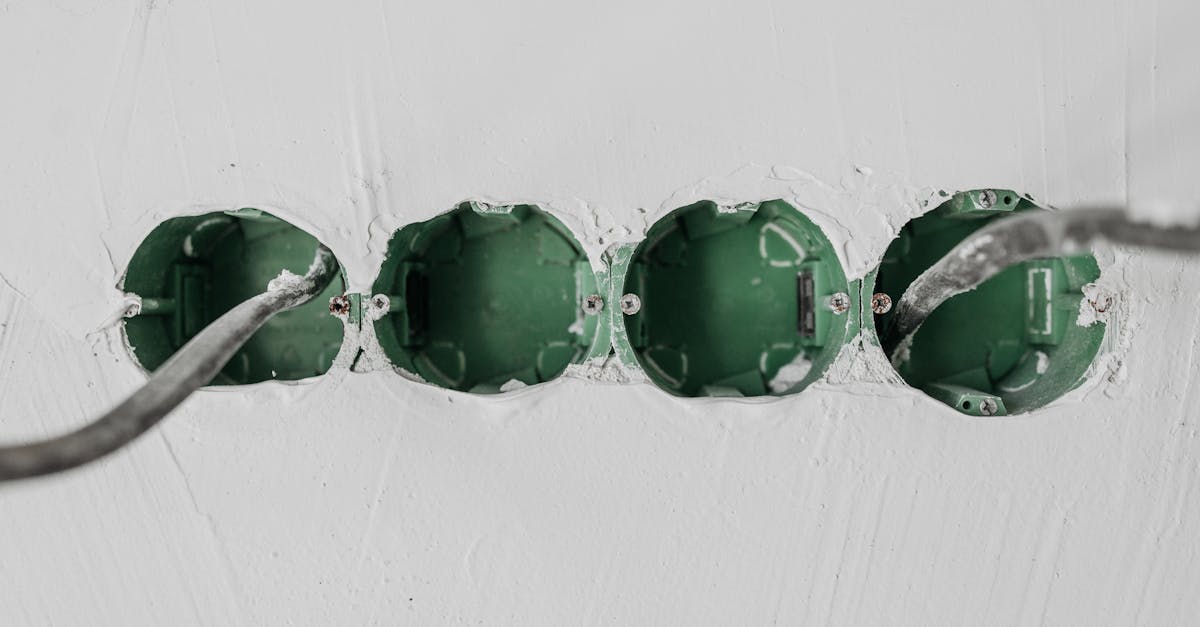

Implementing Safety Protocols

Establishing thorough safety protocols is essential for minimising electrical hazards in the workplace. Each organisation should tailor these protocols to reflect its specific operations and the unique risks associated with its environment. This involves conducting regular risk assessments and ensuring that employees understand and comply with established procedures. Training sessions are a key component of this process, giving workers the knowledge they need to identify potential dangers and take appropriate actions to mitigate risks.

Documentation plays a crucial role in supporting safety protocols. Maintaining clear and accessible records of safety procedures, training sessions, and incident reports facilitates a culture of accountability and continuous improvement. Regular audits and inspections can help organisations identify areas for enhancement and ensure compliance with safety regulations. It is vital for everyone involved to be informed of their responsibilities and to feel empowered to report safety concerns without fear of reprisal.

Developing a Comprehensive Safety Plan

A comprehensive safety plan serves as the foundation for maintaining electrical safety in the workplace. It should be tailored to the specific risks present in each environment, taking into account the nature of operations and the types of equipment being used. Key components include hazard identification, risk assessment, and outlining appropriate control measures. Regular reviews and updates are crucial to ensure the plan remains effective as conditions or technologies change.

Engaging employees during the development of the safety plan is vital. Their insights can help identify potential hazards and effective strategies for mitigation. Training sessions should be included to educate staff about the procedures outlined in the plan. Consistent communication and reinforcement of safety protocols will further embed these practices into the workplace culture, promoting a safer environment for all.

Using Personal Protective Equipment (PPE)

Personal protective equipment plays a crucial role in safeguarding workers from electrical hazards in the workplace. It encompasses a wide range of gear such as gloves, safety glasses, helmets, and insulated footwear. Selecting the appropriate PPE is essential to ensure adequate protection against potential risks. Each piece of equipment should meet relevant safety standards and be suited to specific tasks or environments. Training workers in the correct usage of this equipment further minimises the risk of accidents, ensuring that employees feel confident and can perform their duties safely.

Employers have a responsibility to provide suitable PPE and ensure its availability to all staff. Regular inspections are necessary to identify any signs of wear and tear, which could compromise safety. Providing clear instructions on maintenance and proper care extends the life of protective gear and enhances its effectiveness. Encouraging a culture of safety where workers are empowered to speak up about PPE concerns promotes a safer workplace. By prioritising adequate PPE selection and education, businesses can significantly reduce the likelihood of electrical incidents and create a more secure working environment.

Selection and Usage of PPE

Choosing the appropriate personal protective equipment (PPE) for electrical work is crucial for ensuring safety. Workers must wear gear that meets the specific hazards present in their environment. This includes insulated gloves, rubber-soled boots, and eye protection to guard against potential electrical burns or flash incidents. Employers should regularly assess the risks associated with tasks and ensure that PPE is properly rated for those conditions.

Proper usage of PPE complements the selection process. It is essential for workers to understand how to wear and care for their equipment. Training sessions should provide guidance on the correct fittings, routine inspections, and maintenance practices to ensure maximum protection. Additionally, workers should be encouraged to report damaged or worn-out PPE immediately, as relying on compromised gear can lead to serious injuries.

Emergency Preparedness

Proactive measures ensure a workplace is always ready for electrical emergencies. Training employees on the potential risks and proper responses is crucial. Regular drills can help reinforce protocols and improve familiarity with safety equipment. Clear communication regarding emergency procedures should be established, ensuring everyone knows their roles and responsibilities in case of an incident. Displaying emergency contact numbers and procedures in common areas increases awareness and readiness.

Additionally, creating an accessible and detailed emergency response plan is essential. This plan should outline the steps to take during an electrical incident, including evacuation routes and designated safe zones. Regular reviews and updates to the plan will help accommodate any changes in workplace layout or procedures. Ensuring that all employees have quick access to this information can significantly reduce confusion and improve response time during emergencies.

Creating an Effective Emergency Response Plan

A well-structured emergency response plan is essential for mitigating risks associated with electrical hazards in the workplace. This plan should outline clear procedures for responding to various emergencies, such as electrical fires, equipment failures, or worker injuries. Each team member should be aware of their specific roles and responsibilities during an emergency. Regular training sessions can familiarise staff with the plan and reinforce the importance of their action in a crisis. Additionally, conducting drills will ensure that everyone knows how to respond efficiently and effectively when real emergencies occur.

Incorporating communication strategies into the response plan significantly enhances its effectiveness. Establishing designated communication channels helps keep everyone informed and connected during an emergency. Clear signage and easily accessible information about emergency exits and first-aid stations are critical. Reviewing and updating the emergency response plan regularly ensures it remains relevant and effective. Engaging with staff for feedback on the plan can provide valuable insights and foster a culture of safety within the organisation.

FAQS

What are the key components of a comprehensive safety plan for electrical safety?

A comprehensive safety plan for electrical safety should include risk assessments, safety protocols, training programs, regular inspections, and clear communication of emergency procedures.

How often should personal protective equipment (PPE) be inspected and maintained?

PPE should be inspected before each use and maintained regularly according to the manufacturer's guidelines to ensure it is functioning properly and providing adequate protection.

What types of personal protective equipment are essential for electrical safety?

Essential PPE for electrical safety includes insulated gloves, safety goggles, hard hats, ear protection, flame-resistant clothing, and electrical hazard safety shoes.

How can workplaces effectively prepare for electrical emergencies?

Workplaces can effectively prepare for electrical emergencies by developing and regularly updating an emergency response plan, conducting drills, providing staff training, and ensuring quick access to emergency equipment.

What steps should be taken if an electrical incident occurs in the workplace?

If an electrical incident occurs, immediately shut off the power if it's safe to do so, call for emergency assistance, provide first aid if necessary, and report the incident to a supervisor while documenting the details for follow-up.

Related Links

Case Studies on Electrical Safety Compliance in AdelaideThe Impact of Non-Compliance on Business Operations

Navigating Electrical Safety Regulations for Commercial Projects

Implementing Safety Protocols in Electrical Installations

Common Electrical Safety Violations in Commercial Settings

Compliance Checklists for Electrical Safety in Adelaide Businesses

The Role of AS/NZS 3000 in Commercial Electrical Work

Importance of Regular Safety Audits for Electrical Systems

Understanding Australian Electrical Safety Standards for Commercial Installations